How IoT Redefines Supply Chain Management

The Internet of Things (IoT) is no longer a buzzword—it’s a game-changing force reshaping industries worldwide, including supply chain management. Efficient supply chain operations are often the backbone of successful businesses, and IoT has introduced an unprecedented level of visibility, automation, and optimization to this domain.

If you’re involved in supply chain operations, and logistics, or simply curious about cutting-edge technology, this article will unpack how IoT devices integrate into supply chain management and revolutionize it. You’ll gain actionable insights into its applications, benefits, and potential challenges.

What is IoT in Supply Chain Management?

The Internet of Things refers to a network of connected devices embedded with sensors, software, and other technologies that enable them to communicate and share data in real time. Within supply chain management, IoT devices play a pivotal role by tracking assets, monitoring environmental conditions, automating processes, and providing actionable insights through data analytics.

IoT has extended the reach of supply chain managers beyond merely transporting goods. With smart sensors and devices, companies now monitor factors like location, temperature, humidity, and more. These capabilities result in efficient operations and significant cost savings.

Why Does IoT Matter for Supply Chain?

Imagine having complete real-time visibility across every stage of your supply chain. IoT devices eliminate blind spots, reduce inefficiencies, improve response times, and create leaner workflows—all while cutting operational costs.

5 Key Applications of IoT in Supply Chain Management

1. Real-time Asset Tracking

IoT devices make asset tracking precise and seamless. GPS-enabled trackers and RFID (radio frequency identification) sensors provide real-time updates on goods’ location, ensuring companies know exactly where their products are from warehouse to delivery.

Example in Action

A retail company can use RFID tags to track pallets of products moving across distribution centers, significantly reducing the risk of loss or theft. Similarly, e-commerce businesses can provide customers with accurate, real-time shipping updates.

Impact:

- Improved transparency

- Enhanced operational efficiency

- Better customer experience

2. Condition Monitoring for Sensitive Goods

Temperature-sensitive goods like food, pharmaceuticals, or electronics require stringent conditions during transit and storage. IoT-enabled sensors monitor environmental factors such as temperature, humidity, and air quality, ensuring sensitive goods remain in optimal condition.

Example in Action

Pharmaceutical companies transport vaccines with IoT temperature sensors in cold-chain logistics. The sensors alert supply chain managers to deviations, ensuring product safety and avoiding losses.

Impact:

- Reduced spoilage and wastage

- Compliance with safety standards

- Improved product integrity

3. Predictive Maintenance for Equipment

Machinery failures disrupt supply chains and incur high repair costs. IoT devices help companies perform predictive maintenance by collecting data from equipment sensors. This data identifies potential failures before they occur, ensuring no interruption in operations.

Example in Action

A factory that relies on automated conveyor belts can use IoT sensors to detect wear and tear early, scheduling maintenance before a breakdown slows production.

Impact:

- Reduced downtime

- Lower maintenance costs

- Increased equipment lifespan

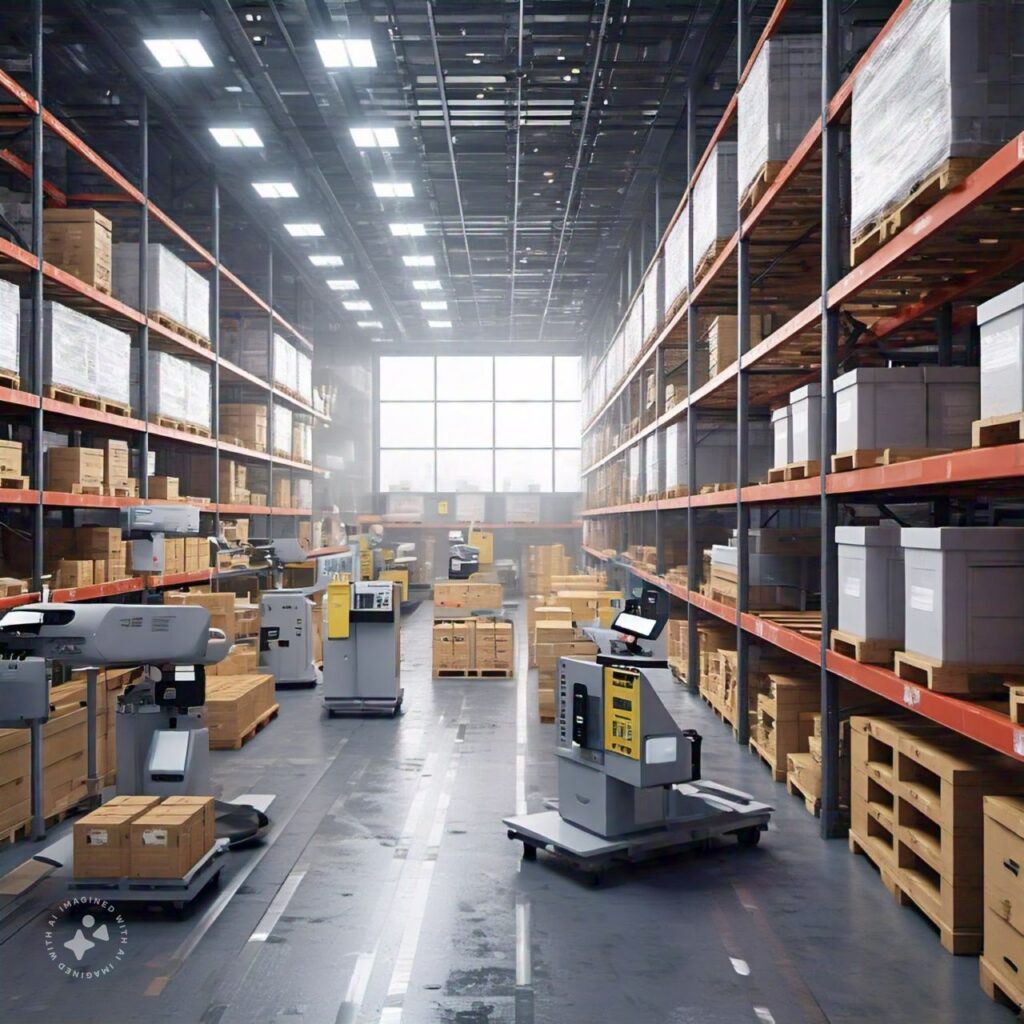

4. Warehouse Automation

IoT has transformed traditional warehouses into “smart warehouses.” IoT-connected devices and robots streamline inventory management, order fulfillment, and resource allocation.

Example in Action

Smart shelves in warehouses can notify systems when inventory is low, automating restocking and preventing supply shortages. Drones equipped with IoT devices can even conduct immediate inventory checks.

Impact:

- Faster processes

- Accurate inventory tracking

- Resource optimization

5. Data-driven Decision Making

IoT generates vast amounts of data that supply chain managers can analyze and leverage for strategic decision-making. Analytics tools connected to IoT devices provide actionable insights that help optimize routing, manage inventory, and reduce waste.

Example in Action

A logistics company using IoT sensors to monitor fleet performance might find more fuel-efficient delivery routes, drastically reducing transportation costs.

Impact:

- Data-backed optimizations

- Reduced costs

- Improved delivery times

Advantages of IoT in Supply Chain Management

1. Increased Efficiency

Automation through IoT reduces manual labor, speeds up routine operations, and minimizes risks of human error.

2. Enhanced Visibility

IoT provides end-to-end transparency by connecting every stakeholder in the supply chain ecosystem.

3. Improved Scalability

IoT capabilities can grow as your business expands, accommodating large-scale data for decision-making.

4. Environmental Sustainability

Optimized processes reduce unnecessary emissions and resource usage, making your supply chain greener and more sustainable.

Challenges in Implementing IoT in Supply Chains

While the benefits abound, challenges cannot be overlooked. These include the cost of IoT device deployment, data privacy concerns, and issues with integration into legacy systems. Yet, with proper planning and investment, businesses often find that the long-term rewards outweigh these hurdles.

How to Get Started with IoT in Supply Chains

If you’re ready to introduce IoT into your supply chain, follow these steps for a smooth transition:

- Assess Your Needs

Identify key bottlenecks in your supply chain. For example, is it tracking shipments or reducing downtime in warehouses? Select IoT solutions tailored to these needs.

- Partner with IoT Providers

Work with reputable IoT service providers who have industry experience. They can recommend customized solutions for your requirements.

- Integrate Gradually

Roll out IoT solutions in phases rather than all at once, reducing implementation complexities.

- Train Your Team

Equip your supply chain personnel with the knowledge and tools to use IoT effectively. Conduct frequent training sessions as the technology evolves.

- Leverage Analytics

Make the most of IoT by pairing it with analytics platforms that convert incoming data into actionable insights.

What’s Next for IoT and Supply Chains?

IoT continues to mature, and its integration with technologies like artificial intelligence (AI) and blockchain promises even greater potential for supply chain innovations. Future developments may include fully autonomous supply chain nodes or dynamic chains adapting in real-time to unpredictable demands.

The companies that adopt IoT early will likely set the bar for cost efficiency, accuracy, and customer satisfaction.

Transform Supply Chains with IoT

IoT is no longer a futuristic concept—it’s a current necessity for businesses aiming to enhance their supply chain operations. By adopting IoT, you can redefine your supply chain management with greater visibility, efficiency, and scalability. With the rapid advancements in this sphere, the possibilities are endless.

Unlock the full potential of IoT for your supply chain today. Don’t get left behind—your efficiency, bottom line, and customers will thank you for it!

Conclusion

The integration of IoT into supply chain management is revolutionizing the way businesses operate. By leveraging real-time data, automation, and enhanced tracking capabilities, IoT empowers organizations to streamline their processes, reduce costs, and improve overall efficiency. Companies that adopt IoT now will not only gain a competitive edge but also future-proof their operations in a rapidly evolving market. Take the step to incorporate IoT into your supply chain strategy and reap the rewards of smarter, more agile operations. The future of supply chain management is here—embrace it today!

FAQs about IoT in Supply Chain Management

1. How secure is IoT for supply chain management?

IoT can improve supply chain security through real-time monitoring and traceability, but security risks must be carefully managed.

2. How does IoT help reduce costs in supply chains?

IoT can reduce supply chain costs by improving inventory management, optimizing transportation, and enhancing asset utilization.

3. Can small businesses afford IoT in supply chains?

Small businesses can afford IoT in supply chains through cost-effective solutions and gradual implementation.

4. Which industries benefit most from IoT in their supply chains?

Manufacturing, retail, and transportation.

5. What is the ROI for IoT in supply chains?

The average ROI for IoT in supply chains is 16-27%.